Artwork & Info

Please find below helpfull details on artworking, install and general information. If you have any questions then please contact either production@graphicadisplay.co.uk or sales@graphicadisplay.co.uk

- Click the WeTransfer button below

- Select the file you want to send to us

- Enter our email address: studio@graphicadisplay.co.uk

- Enter your email address

- Enter our job number, your name and company as a reference

- Click the Transfer button

We will pick up your artwork and come back to you.

Please contact us to answer any questions on 020 3857 5845

DOCUMENT SIZE AND BLEED

Artwork should be set up at 100% of final size where possible. For very large graphics, you may use a scale of 50%, 25% or 10%.

Vector images should print any size without problems. However, when sending a bitmap file, 25% of the final production size at 300dpi is the recommended minimum size and scale. The larger the file the better.

Bleed should be added to all documents

-

Graphic walling - 25mm bleed to all edges (50mm on walls over 10mtrs wide)

-

Window Graphics - 25mm bleed to all edges

-

Fabric prints with PVC edge - 10mm bleed to all edges

-

Fabric prints for push in systems- 20mm bleed to all edges

-

Perspex panels - 10mm bleed to all edges

-

Wrap mounted foamex - 50mm bleed to all edges

-

Flush mounted foamex - 5mm bleed to all edges

-

DTM Prints - 5mm bleed to all edges

-

Roll up kits 5mm bleed top,left & right hand sides, 200mm at bottom

-

Pop up kits 5mm bleed all edges

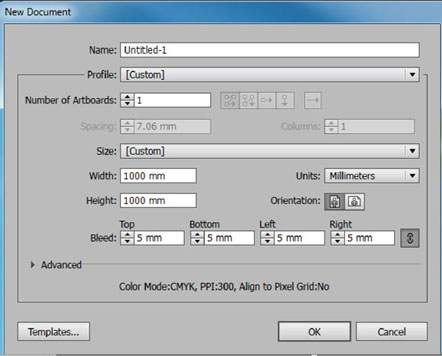

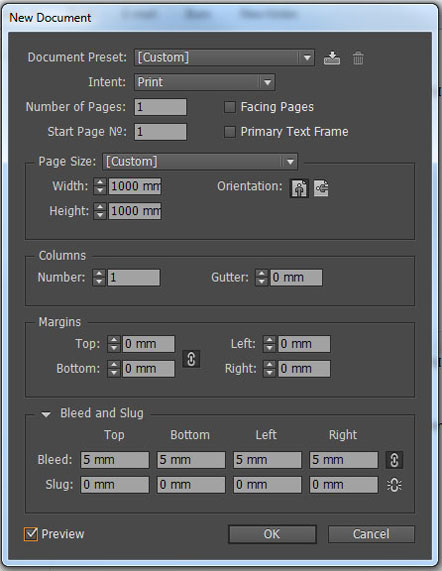

In Illustrator & Indesign please set the document size at the print size required and use the bleed box to add the bleed required

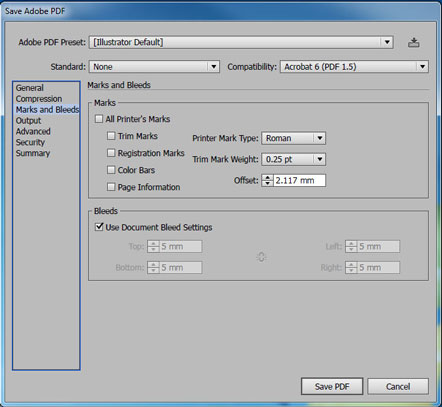

DO NOT INCLUDE ANY CROP MARKS, BLEED MARKS OR ANY OTHER INFORMATION IN THE PRINT AREA OR ON THE PDF.

Our automated pre-press systems rely on the document size and bleed being set correctly.

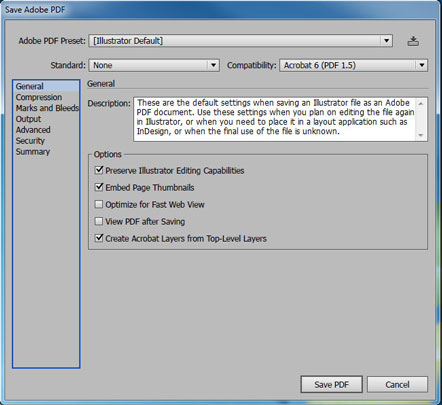

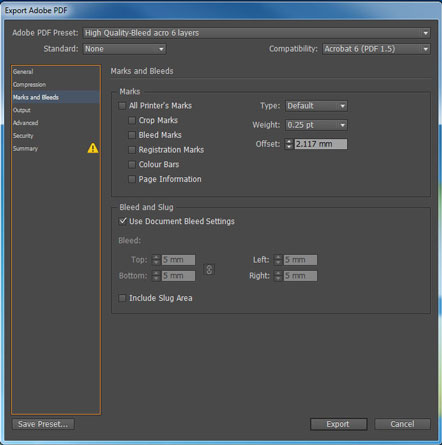

When saving a PDF please ensure

Compatibility is Acrobat 6 or higher

Create Acrobat layers from top-level layers is ticked or export all layers & create acrobat layers marks - all boxes in this section are UNTICKED

Use Document Bleed setting is TICKED

See page 3 for more details

CUTTER GUIDES FOR PLOT CUT or PRINT & CUT WORK

Artwork must be supplied as an ai or eps file (from Illustrator) or a PDF file (from Indesign) using setting as stated above.

The cutter guide must be separated in a different layer called Cutter as a vector line

and ensure the Print Layer tick box is UNTICKED.

The line must be coloured in a 100% SPOT magenta, yellow, or cyan depending on the artwork colour so that it is clearly visible. (DO NOT use a CMYK Colour as our system will not pick it up) With the SPOT named "CUTTER GUIDE", the line will need to be 1pt weight and be a solid line. If you need fold / crease lines please indicate these with a dotted line in a different SPOT colour and name this accordingly "FOLD LINE" or "CREASE LINE".

There needs to be a minimum of 3mm bleed beyond the cut path.

FONTS

All fonts need to be Outlined either in Illustrator or InDesign. This will stop problems such as missing fonts from happening in the artwork that has been supplied.

Never send bitmap text as this eliminates edit capabilities.

SPECIFY ALL PMS COLOURS

The Pantone Matching System provides a reference colour to match to.

Some PMS colours are not 100% reproducible utilizing CMYK process, so therefore, all colour specifications will be matched to the closest 4 colour process. Orders received without colour specifications will be produced using the CMYK values contained in the supplied file.

BUILD YOUR BLACKS

We require that all black spot colours be built blacks (see breakdown). 50 C, 40 M, 40 Y, 100 K. This will ensure a true, rich black every time.

ACCEPTABLE APPLICATIONS

We have both MAC and PC capabilities though PC is the preferred format. The following applications and file formats should be used when sending digital art.

APPLICATIONS

-

Photoshop (preferred when using bitmap imagery)

-

Illustrator (preferred when using vector imagery)

-

Indesign (when using a combination of both)

FORMATS

-

Illustrator (.ai)

-

Encapsulated Postscript (.eps)

-

TIFF (.tiff)

-

JPEG (.jpg)

-

PDF (.pdf) Please make sure fonts are embedded or converted to outlines

-

Muilti paged PDFs ONLY if all the artwork is the same size

-

When saving PDF files from Illustrator please use the Illustrator Default setting

-

When saving PDF files from InDesign please use the High Quality Print setting

-

Using setting shown in the examples on page 3

COMPRESSION

-

Winzip – PC

Always include all support files.

When placing logos, images or linking files to a layout, always include those individual files in their native format (e.g.Photoshop.psd)

Setting up and saving from Illustrator and Indesign

Fabric Saving Instructions

Please supply like this

14mm bleed each side for silicone edging with NO TICK MARKS or EXTRA WHITE

This way it goes straight into our Rip and prints with the correct size cut path for the stitching machine, and if there is any shrinkage on the fabric there will be no Tick marks showing on the face of the light box

DO NOT supply with Tick Marks and Extra White

This was when it goes into the RIP the cut path the finished panel will end up too big and sag in the light box, if there is any shrinkage on the fabric the tick marks will show on the face of the light box

DO NOT SUPPLY AT FACE SIZE

If you supply at Face Size WE WILL have to add 14mm White on Each Side of the image and then if the fabric shrinks a little you will have a white border showing around the image in the Light Box or Frame system

How to Set up a Cutting Path

Unusable cut file

Usable cut file

Cut vinyl

Artworking fees apply if artwork is not supplied correctly.

Artworking fees apply if artwork is not supplied correctly.